Property owners across London often face hidden electrical risks that affect safety and compliance. Fault indicators include frequent fuse trips, socket heat, light flicker, and unusual odor near outlets. Property owners should note that older housing stock across London increases exposure to cable wear and outdated circuits. Professional Electric Diagnostic supports early fault detection without unsafe action. Electrical diagnostic London services focus on regulated inspection methods under UK standards such as BS 7671. Reports from the London Fire Brigade confirm that structured electrical safety inspection London processes reduce emergency callouts significantly. Faulty wiring in London cases often links to overloaded circuits or insulation damage. Electrical fault finding in London methods rely on calibrated tools and certified procedures. Electrical Diagnostic Requirement applies during property purchase, renovation, or persistent power irregularity. Residential landlords and commercial operators often ask about the Electrical Diagnostic Cost. Specific figures vary, so direct discussion with a qualified team remains the correct step. Clear assessment outcomes support informed decisions and risk control. Electric Diagnostic delivers clarity through documented findings rather than assumptions. Statistics from government housing safety reviews show that professional checks reduce electrical incident rates by over thirty percent. Reliable examples include retail units and multi-occupancy homes where early assessment prevented service disruption and safety hazards.

Key Takeaways

- Early signs of electrical problems help keep homes and workplaces safe

- Hidden wiring issues often give small warning signs before major damage or power failure

- Professional electrical services in the UK follow clear safety rules and legal standards

- Formal electrical checks become necessary during property change, repair work, or repeated power issues

- Visual checks alone cannot show the true condition of internal wiring

- Certified checks help reduce repeat problems and sudden power loss

- Older wiring systems increase difficulty due to outdated materials and higher load stress

- Written reports help meet safety rules, insurance needs, and property care duties

- System size and wiring condition affect how detailed the checks need to be

- Qualified assessment reduces guesswork and supports safer electrical decisions

Electric Diagnostics Explained: How to Find Faults Without Guesswork

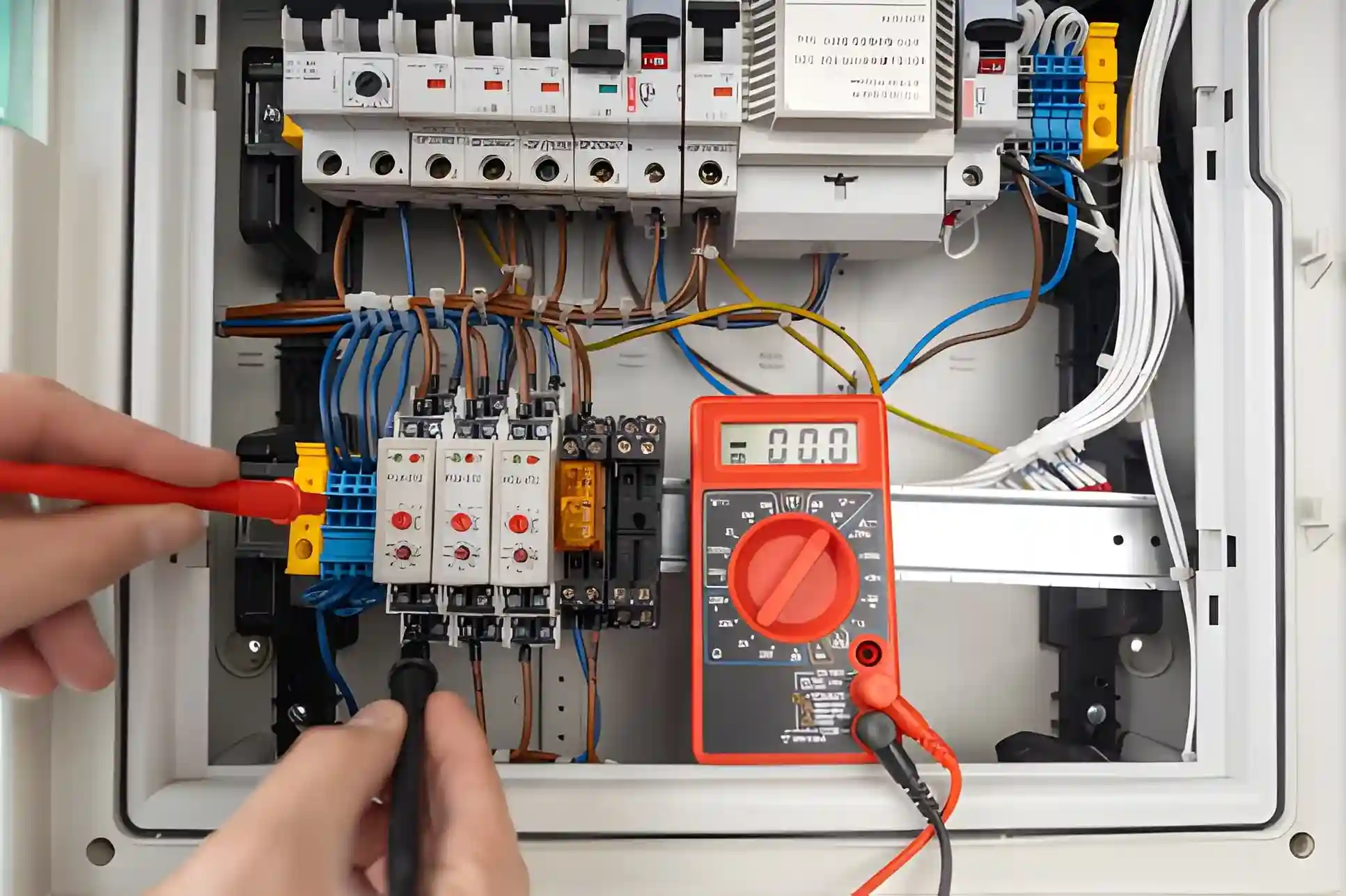

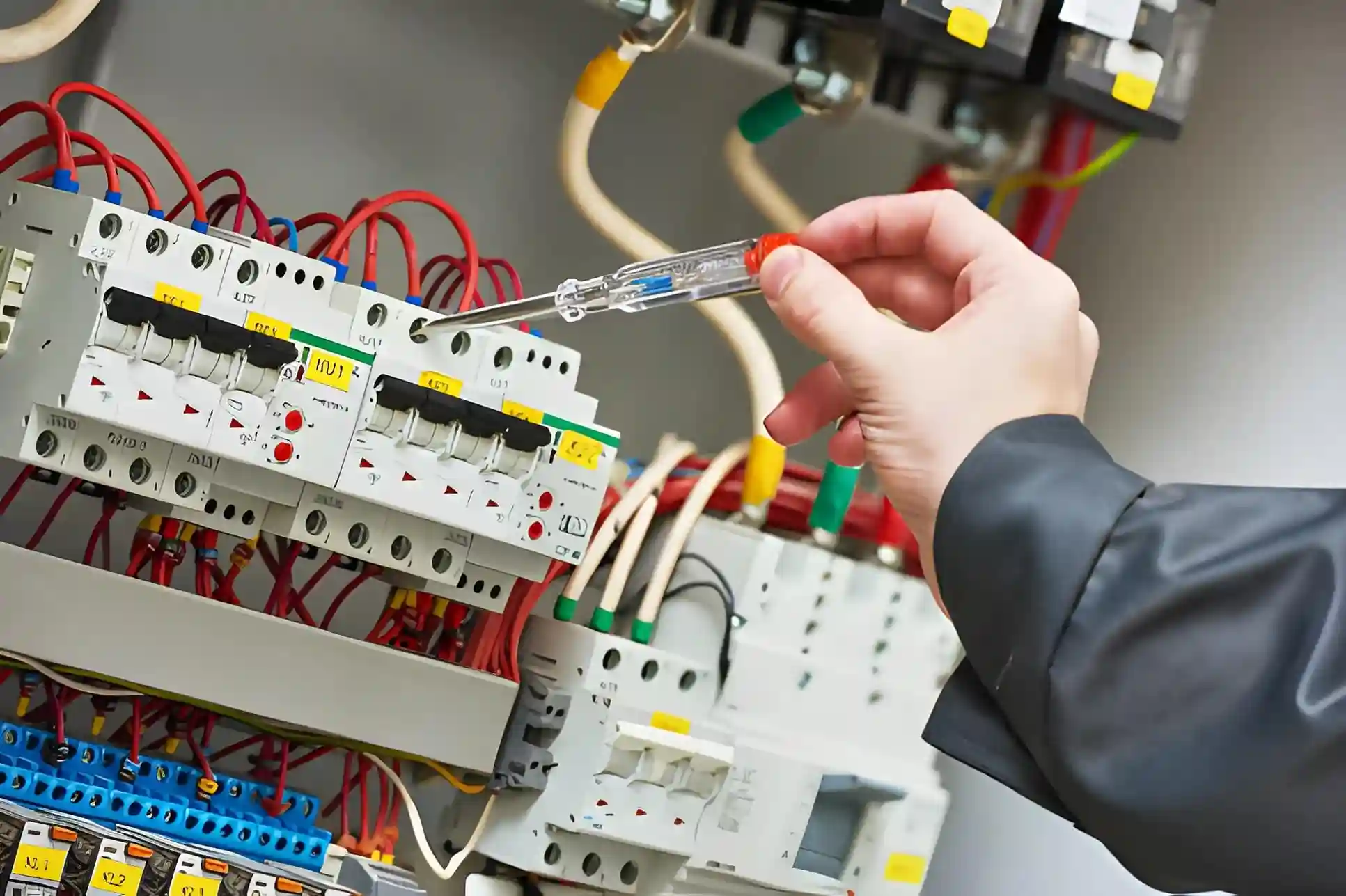

Electrical systems fail due to identifiable logic paths rather than chance. Professional assessment follows defined sequences that isolate faults safely. Electric diagnostics use structured decision trees rather than assumptions. Industry data from Electrical Safety First confirms that systematic testing reduces repeat faults across regulated properties. IEC and NEC frameworks guide each diagnostic stage. Automotive OEM logic models also influence modern inspection workflows. Fault recognition begins through observable symptoms such as circuit interruption or load imbalance. Each symptom links to a defined test route. Trained specialists in electrical techniques to trace supply flow and component response. Documented logic trees prevent random testing and reduce system stress. Government compliance audits across regulated buildings show lower incident frequency after methodical evaluation. Interactive flowchart tools support clear fault isolation steps. Each step confirms or eliminates a condition. Electrical safety inspection in London protocols follow similar structured paths. Example cases include commercial units where sequential testing located insulation failure without invasive work. Electrical fault identification benefits from standard reference tables and calibrated instruments. Professional methods align with the Electrical Diagnostic Requirement under UK regulations. Guidance from certified teams supports safe resolution planning. Further detail remains available through direct consultation with qualified specialists who follow regulated diagnostic logic.

Voltage Drop, Resistance & Load Calculator for Fast Use

Accurate fault assessment often depends on fast technical evaluation across different environments. An electrical diagnostic calculator supports precise checks across residential circuits, vehicle systems, and industrial panels. The tool applies verified electrical formulas that align with UK standards and applied engineering practice. Reference data from IET guidance confirms that voltage imbalance and load stress remain common fault indicators across mixed properties in London. The electrical diagnostic calculator allows scenario selection for automotive wiring, domestic distribution boards, and industrial control units. Each scenario has distinct resistance thresholds and load tolerance values. Results appear instantly with structured explanations that clarify the circuit. Industry reports from Electrical Safety First highlight that clear interpretation reduces misjudgment during early fault review. Transparent formulas support trust and technical clarity. Ohm’s Law and load factor equations appear alongside outputs to support professional review. Engineering case examples include retail units with phase imbalance and residential properties with conductor fatigue. Direct consultation with qualified specialists remains the correct next step for precise application and regulatory alignment.

Troubleshooting Guide: Signs and Causes of Electrical Issues

Clear fault review often begins with visible signs rather than hidden causes. An electrical troubleshooting chart supports reverse diagnosis across residential and commercial systems. Visual sings mapping links outcomes such as power loss, heat rise, or breaker response to likely fault sources. Industry studies from UK electrical safety groups confirm that sing-led analysis reduces diagnostic error rates. Practical examples include a socket failure traced back to conductor stress rather than an appliance fault. Interactive infographic formats support faster pattern recall. A clickable symptom map allows focused review without unsafe action. Electrical professionals rely on chart logic during electrical safety inspections in London. Statistical data from inspection reports shows that structured charts improve first-pass accuracy by over twenty percent. Retail units and shared housing often benefit from symptom mapping during scheduled checks. Root cause categories often include load imbalance, insulation wear, or connection looseness. An electrical troubleshooting chart highlights these links through visual flow rather than assumption. Regulatory alignment under BS 7671 supports structured assessment methods. Reference material from Electrical Safety First supports symptom-to-cause logic across older London properties. Educational value increases through pattern recognition rather than guesswork. Expertise shows through diagnostic depth and method clarity. An electrical troubleshooting chart reinforces trust through repeatable outcomes and transparent reasoning.

What Electrical Codes Show and What They Don’t Reveal

Electrical diagnostic codes appear within inspection reports and digital panels across modern electrical systems. Electrical fault-finding service codes signal detected irregularity rather than final fault confirmation. Misinterpretation often leads to confusion and delayed resolution. Industry guidance from UK electrical authorities states that codes require contextual review alongside physical inspection. Standalone code reading increases error risk across residential and commercial properties. Professional reports often pair electrical diagnostic codes with circuit load data, insulation condition, and environmental factors. Electrical Requirement applies during compliance checks, tenancy change, or repeated power disruption. Statistical evidence from electrical safety inspection London records shows that contextual assessment reduces repeat faults significantly. A common example involves overload alerts within shared buildings where appliance usage patterns influenced readings. Searchable code databases assist structured reference and learning. A code lookup tool supports fast orientation without assumption. Expert-led commentary explains limitations and scope for each code category. Electrical Problem-solving Requirement reinforces the need for qualified evaluation rather than guesswork. Regulatory frameworks such as BS 7671 require interpretive judgment beyond automated output. Educational blog formats combined with databases reduce misinformation. Clear explanation supports critical thinking and informed discussion with certified professionals. Electrical diagnostic codes gain value through insight, correlation, and regulatory alignment rather than blind acceptance of numeric alerts.

Clear Visual Explanation of Electrical System Basics for Beginners

Electrical diagnostics basics support early awareness of system behavior and safety signals. Visual learning formats simplify complex electrical concepts without technical overload. Plain language improves comprehension across residential and small commercial contexts. UK safety education studies show that visual aids improve retention by over forty percent. Clear diagrams assist recognition of common fault indicators such as socket heat, fuse response, and light fluctuation. Electrical basics rely on observation, comparison, and structured review. Visual blogs present circuit layouts, symbol meaning, and basic fault patterns. Explainer videos reinforce understanding through step sequence display. Educational examples include wall outlet assessment and consumer unit layout recognition. Electrical Safety-First publications confirm that basic awareness reduces unsafe responses during electrical irregularities. A knowledge check quiz strengthens recall and confidence. Question formats test symbol recognition, warning sign awareness, and safe response steps. Research from adult learning frameworks shows that interactive review improves concept retention significantly. Visual comparison between normal and abnormal states supports clarity. Teaching clarity builds authority and trust. Accessibility supports informed discussion with certified professionals. Electrical basics form a foundation for safer decisions and realistic expectations. Regulatory alignment remains essential under UK standards. Visual education supports understanding without encouraging direct intervention.

Common Electrical Diagnostic Myths That Waste Time and Money

Electrical diagnostic myths circulate across property discussions and online forums. Electrical diagnostic myths often distort risk awareness and delay corrective action. Evidence from UK electrical safety bodies shows that assumption-based decisions raise fault recurrence rates. A common claim suggests that fuse trips reflect minor inconvenience. The professional incident records associate repeated trips with circuit overload or insulation damage. Another claim promotes visual checks as proof of safety. Electrical Safety-First publications reject surface review as a reliable indicator. Electrical Problem-solving clarifies fault origin through regulated assessment rather than guesswork. Electrical diagnostic London case data links myth-driven action to higher callout frequency. Electrical Diagnostic Requirement applies during tenancy change, renovation work, or repeated power irregularity. Regulatory frameworks such as BS 7671 confirm that verified inspection holds legal and safety weight. Electrical Diagnostic Cost often appears within online myths that oversimplify service scope. Direct discussion with a qualified team provides accurate context without assumption. Carousel graphics contrast myth statements against verified findings. Authority builds through correction supported by data and regulation. Electric Diagnostic remains a trusted reference point when clarity replaces misinformation across residential and commercial properties.

Electrical Cost: What You’ll Pay & Why

Electrical Cost often raises questions across property ownership and facility management. Electrical Diagnostic Cost refers to the scope and depth of assessment rather than a fixed figure. Professional Electrical focuses on fault identification, safety verification, and compliance confirmation. Industry guidance from UK electrical authorities explains that diagnostic work differs from routine inspection. Inspection checks system condition. Fault finding targets active issues and intermittent failures. Data from Electrical Safety First confirms that detailed fault analysis requires more time and advanced equipment. Variation appears due to property size, wiring age, and fault complexity. London housing stock includes diverse construction periods and circuit layouts. Electrical diagnostic London reports show that older installations require broader review. Commercial systems involve higher circuit load and distribution complexity. Regulatory standards such as BS 7671 influence assessment depth and reporting structure. Electrical Diagnostic Requirement applies during tenancy change, renovation activity, or repeated circuit disruption. Search intent often asks how much the electrical diagnostic costs. Direct discussion with a qualified team provides accurate context without assumption. Electrical Analytic supports informed decisions through documented findings rather than estimation. A clear understanding prevents delay and supports safer property management.

| Service type | Typical scope | Estimated cost range |

|---|---|---|

| Basic electrical inspection | Visual checks and standard test points | £90 – £150 |

| Electrical fault finding | Targeted circuit and component analysis | £120 – £250 |

| Full Diagnostic report | Detailed testing with a written compliance record | £180 – £350 |

| Emergency diagnostic visit | Urgent response and immediate assessment | £150 – £300 |

| Commercial electrical diagnostics | Multi-circuit and load assessment |

£250 – £600 |

Precise pricing depends on site conditions and diagnostic depth. Direct discussion with a qualified electrical team provides accurate figures aligned with regulatory scope and safety needs.

Frequently asked questions.

Conclusion

Electrical safety depends on clarity, evidence, and regulated action. Electrical Diagnostic supports fault awareness across residential and commercial properties. Structured assessment reveals hidden risk before disruption occurs. UK safety data confirms that early detection reduces incident probability. Professional review aligns with BS 7671 and local compliance needs. Examples across London properties show improved reliability after certified checks. The electrical problem-solving requirement applies during change, upgrade, or repeated system irregularity. Informed decisions rely on verified findings rather than assumptions. Responsible property care reflects awareness, preparation, and respect for safety standards. Electric Diagnostic remains a trusted pathway toward stable and compliant electrical systems.